Address

Building 1, Zone 1, Greenland Binhu International City, Zhengzhou, Henan, China

Work Hours

Monday to Friday: 9AM - 7PM

Weekend: 10AM - 6PM

Address

Building 1, Zone 1, Greenland Binhu International City, Zhengzhou, Henan, China

Work Hours

Monday to Friday: 9AM - 7PM

Weekend: 10AM - 6PM

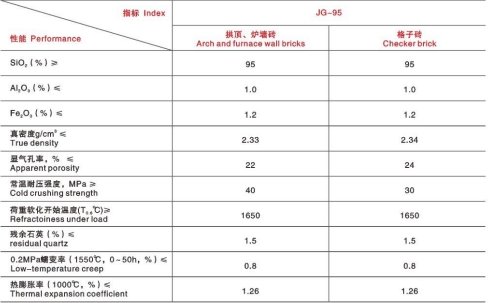

Silica Brick for Coke Oven is a refractory material specially used in coking ovens (i.e. coke ovens). Its main component is silicon dioxide (SiO₂), which has excellent high temperature resistance and thermal shock resistance. In the application of coke ovens, silica bricks are mainly used in furnace walls, furnace bottoms and other parts to withstand harsh conditions such as high temperature, thermal shock, and chemical erosion during the coking process.

High temperature tolerance: The silica content of silica bricks is usually above 95%, with a high melting point and high temperature resistance. During the coking process, the temperature inside the coke oven can reach 1000℃ to 1300℃, and silica bricks can work stably in such a high temperature environment.

Thermal shock resistance: During the use of the coke oven, the temperature inside and outside the furnace changes greatly, which is easy to cause thermal shock caused by temperature difference. Silica bricks have good thermal shock resistance and can withstand rapid temperature changes without cracking or damage, extending the service life.

Excellent chemical stability: Silica bricks have strong resistance to chemical erosion and can withstand the erosion of the complex chemical environment in the coke oven, especially the strong resistance to acidic substances (such as sulfur, chlorine, etc.) at high temperatures. This feature enables silica bricks to effectively protect the coke oven body and reduce corrosion and damage.

Low thermal expansion coefficient: Silica bricks have a low thermal expansion coefficient, which can reduce deformation caused by temperature changes, which helps to maintain the stability of the furnace structure and improve overall durability.

Long service life: Due to the advantages of silica bricks such as thermal shock resistance, high temperature resistance and chemical corrosion resistance, they can work stably for a long time in the coke oven, reducing the need for frequent replacement of the furnace lining.

Coking furnace body structure: Silica bricks are widely used in key parts such as the furnace wall, furnace bottom and furnace roof of the coke oven. Since the atmosphere in the coke oven is relatively complex and the temperature is extremely high, silica bricks can provide strong protection.

Metallurgical industry: In the coking process of the steel industry, silica bricks are not only used to produce coke, but also used in other structures in high-temperature furnaces to withstand the erosion of molten metal and slag in the furnace.

Other high-temperature equipment: Silica bricks are also widely used in other high-temperature industrial equipment, such as cement kilns, glass kilns, ceramic kilns, etc. Its excellent high-temperature resistance and corrosion resistance make it widely used in these fields.

High temperature resistance: It can work stably at temperatures up to 1300°C to meet the long-term high-temperature requirements of coke ovens.

Thermal shock resistance: It can withstand temperature differences between the inside and outside of the furnace and reduce damage caused by temperature changes.

Chemical erosion resistance: It has strong tolerance to acidic substances and effectively protects the coke oven from chemical erosion.

Long service life: Under high temperature and harsh conditions, it maintains a long service life and reduces the frequency of maintenance and replacement.

In summary, silica bricks for coke ovens are an indispensable key refractory material in the coking industry. Its high temperature tolerance, thermal shock stability and chemical corrosion resistance make it an ideal lining material for high-temperature equipment such as coke ovens.